THE RAW MATERIAL

The pig destined to confer the leg that will become “Parma ham” must have precise characteristics regarding the origin area and the breed. Such pigs can be given to birth and bred only in 10 regions of north-central Italy. Just in presence of these requirements, certified by the documentation and by the brand put by the breeder, the pig can be slaughtered; its age must be between 9 and 15 months ; about 160 Kg (and anyway not less than 144 Kg) of weight; healthy and it must have fasted for 15 hours. After slaughtering the fresh leg is isolated from “mezzena“ (half-carcase).

COOLING

The fresh leg spends 24 hours in suitable cooling stores till reaching a temperature of 0 C° so that the meat gets harder in the cold and is able to be trimmed easier. During the cooling phase, the product has a first weight loss of about 1%. Besides, the legs used for the production of Parma Ham must not undergo any conservation or freezing treatment.

TRIMMING

It serves to confer to Parma Ham the characteristic rounded shape. The trimming is carried out by removing part of the fat and the rind also for a technical reason, as it helps the following salting. With the trimming the leg loses fat and muscle for 24% of its weight; during this operation the legs showing even small imperfections are rejected.

SALTING

(the first 24 days)

The cooled and trimmed leg is delivered to our production plant every week. The salting is carried out in a diversified way: the parts of the rind are treated with humid salt and the thin parts are treated with dry salt. This extremely delicate operation is hand-made by expert operators: it must be carried out on legs at an adequate and uniform temperature. A leg, that is too cold, absorbs little salt, whereas a leg that is not cold enough may deteriorate. Chemical substances, preservatives or other additives, and the smoking process are not used. The leg is then stored in a cold storage room at a temperature between 1 and 4 C°, with about 80% of humidity. After a week in this storage room called “di primo sale” (first salt) we remove the residual salt and we salt the leg again. Then we put it again in a new cold storage room, called “di secondo sale” (second salt) and it remains there for 18 days.

After this salting period the weight loss is about of 4%, as the meat loses part of its humidity, by absorbing slowly the salt.

RESTING PERIOD

(from the 24th day to the 94th)

Once the residual salt has been eliminated, the leg remains for 70 days in a suitable storage room called “di riposo” (resting room), with humidity of about 75% and a temperature ranging from 1 to 4 C°. During this phase, it must “breathe” without becoming either too wet or too dry. The absorbed salt penetrates deeply spreading evenly inside the muscular mass and the weight loss is about equal to 12/14%.

WASHING AND DRYNG

(from the 94th day to the 108th)

After the resting period, the leg is washed with lukewarm water to remove possible salt crystals or impurities. The following drying takes place by taking advantage of the natural environmental conditions, during the dry and windy sunny days, or in suitable dryers in which the convective movements of the air are duly exploited.

PRE-CURING

(from the 108th day to the 180th)

The hams continue the curing process in large rooms with staggered windows. The windows are opened according to the conditions of the inside humidity, both with respect to the outside climatic humidity and to the one of the product. This operation must allow a gradual and constant product drying. The weight loss is equal about to 8%.

SMEARING

(carried out on the 180th day)

The smearing is useful to soften the surface muscular layers by avoiding a too rapid drying with respect to the inside ones, even allowing a further humidity loss. The uncovered muscular part is covered with “smear” by expert operators. It is a paste of ground pork fat with addition of a little bit of salt, ground pepper and rice flour. The “smear” is not considered ingredient by the Italian legislation, as it is a completely natural slaughtering product without any type of preservative.

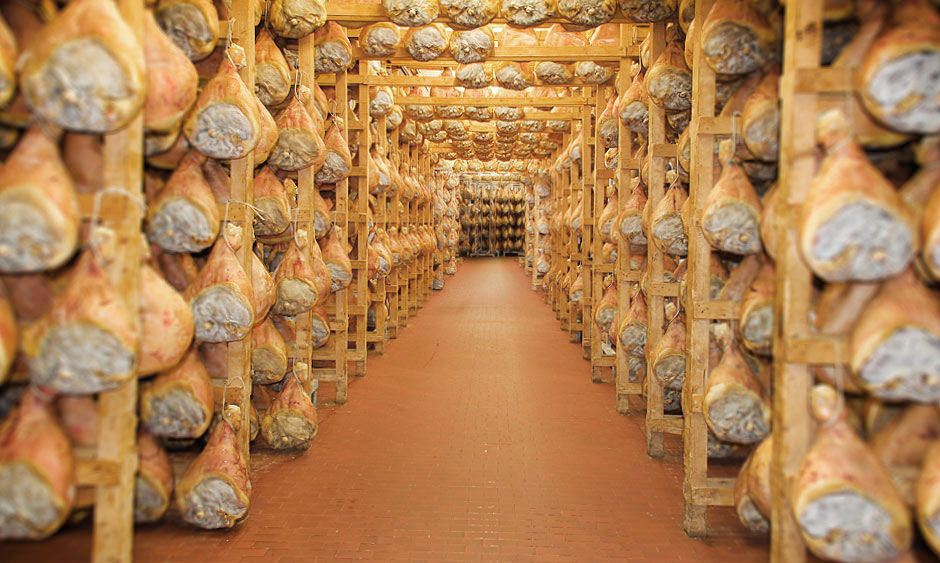

CURING

(rom the180thday to the 365th)

In the 6thmonth, our hams are transferred to the cellars. The production area in which our plant is situated confers an essential added value to the ham curing, as the particular environmental characteristics have their important influence. During this phase, important biochemical and enzymatic processes take place determining together the characteristic perfume and taste of Parma ham. During the curing the weight loss is about of 5%.

TEST AND BRANDING

(carried out starting from the 365th day)

At the end of the curing process, we carry out the test operations, a fundamental exam of olfactory method. In this phase a horse bone needle is inserted into various points of the muscular mass; this material has the particularity to absorb the product aromas and then to lose them quickly. The needle is “smelled” by our experts trained to recognize and to evaluate the olfactory characteristics in order to check the good progress of the productive process. After at least twelve months and after suitable controls carried out also by the Officers of the Istituto Parma Qualità (Parma Quality Institute) the fire-branding of the five-point crown is affixed. This certification is the last one of a series guaranteeing the control happened in each phase, by indicating also the code B22 identifying our production plant. The legal mark of the Consorzio del Prosciutto di Parma (Parma Ham Consortium) indicates that the fire-branding is not only a true State stamp but also guarantee of aroma and quality and the absolute respect of the traditional methodology that was confirmed also legally (L. 26 dated 13th February 1990 and Legislative Decree 253 dated 15th February 1993).

FINAL CURING AND SHIPMENT

(from the 365th day to the 500th)

The curing continues by conserving the hams at controlled temperature and humidity till the 16th month. On that date Parma hams will undergo a last control and a last test. If they are considered perfect, cured and ready for the magic meeting on the banquet table, they are sent to the client.

The curing cycle is a very long transformation process in which a fresh leg of a certified Italian pig becomes a certified Parma raw ham. This can be called a true “miracle”. For at least 500 days, till the day reaching our tables, Parma raw ham is produced by using, as unique conservation ingredient, the dried marine salt. Besides, it is cured by exploiting the famous microclimate, characteristic making our territory unique in the world.